These ingredients make our beers unique

Our beers are unique. They owe their unmistakeable flavour to the high-quality ingredients we use when brewing, our tailored brewing process based on the German Purity Law and our employees’ years of experience.

Water

We extract the water we use to brew Gilde beers from our own wells at the Hildesheimer Strasse site.

Malt

The barley malt that we use in our brewing process comes from experienced maltsters in Germany. The type and composition of the malt significantly influence the colour and flavour of our beers.

Hops

We use the finest hop varieties to brew our beers. We source them primarily from the largest contiguous growing area in Hallertau and partly from Lake Constance in Tettnang. The hops give our beers their refined, bitter taste and make them last longer.

Yeast

Yeast sets the alcoholic fermentation in motion. We cultivate and maintain pure yeast strains, which play a key role in determining the character of our beers.

Expertise and passion

The most important ingredients of all are our employees. With their years of expertise and passion, they oversee all processes from receiving the raw materials to creating the finished products.

Milling

In the first step, we mill our barley malt so that it dissolves better in water.

Mashing

Next, we mix the malt grist with water in the mash tun. This converts the starch into sugar.

Lautering

In the lauter tun, we filter the mash and separate the solid components, the so-called spent grain, from the liquid components, the wort. While the wort plays an essential role in the further brewing process, the spent grain is usually used as nutritious animal feed.

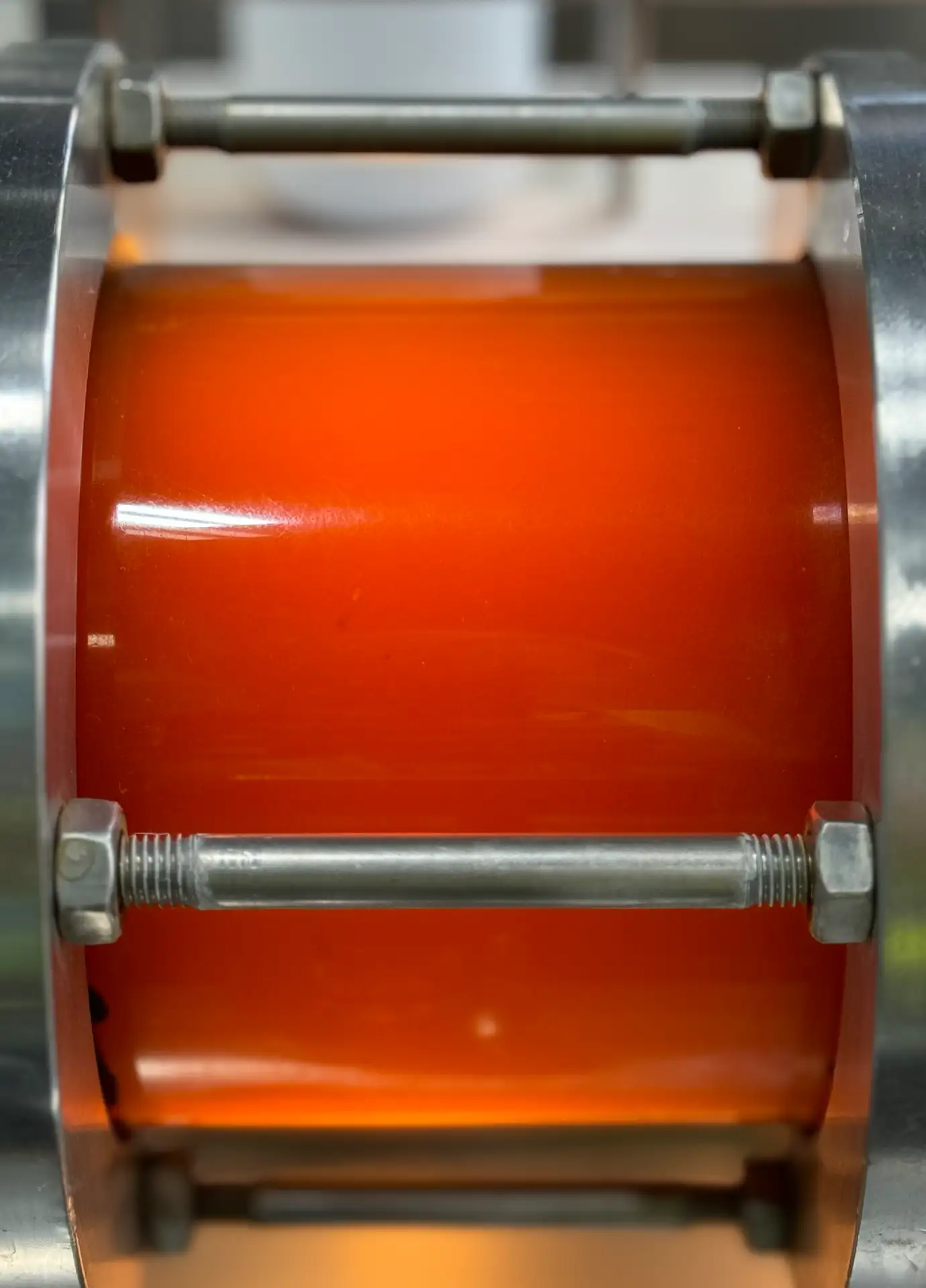

Wort

We boil the wort in the wort pan and add hops. The more hops we add, the more bitter the beer becomes. Of course, the type of hops also plays a role. After the boiling process, we add the wort to the whirlpool, where any remaining impurities are removed.

Fermentation

When the wort has cooled to a certain fermenting temperature, we add our yeast and start the fermentation process. The sugar is converted into alcohol and carbon dioxide. This turns the wort into Gilde green beer or young beer, which is then kept in cool storage while it matures.

Filtering

One of the last steps in the brewing process is filtering, which removes any remaining impurities from the beer.

Filling

Our Gilde beers are now ready to go into our typical bottles, cans and barrels.